The shaking table, also known as a gravity concentration table, is a fundamental device primarily used in the fine particle concentration stage of mineral processing. It serves as a highly efficient separator for recovering valuable minerals based on differences in density. This equipment is particularly effective for processing a wide range of minerals, including but not limited to tin, tungsten, tantalum, niobium, gold, iron, manganese, chromium, and various rare earth metals. It excels at treating fine-grained materials, typically within a size range of 0.019mm to 2mm.

Shaking tables are commonly integrated into gravity separation circuits within various processing plants. They are frequently seen in setups for alluvial sand processing plants (like beach sand), tungsten-tin beneficiation plants, and gold recovery plants. They often work in conjunction with other equipment such as crushers, ball mills, spiral classifiers, and jig machines to form a complete gravity concentration production line, where the table acts as the final, high-precision cleaning or scavenging unit.

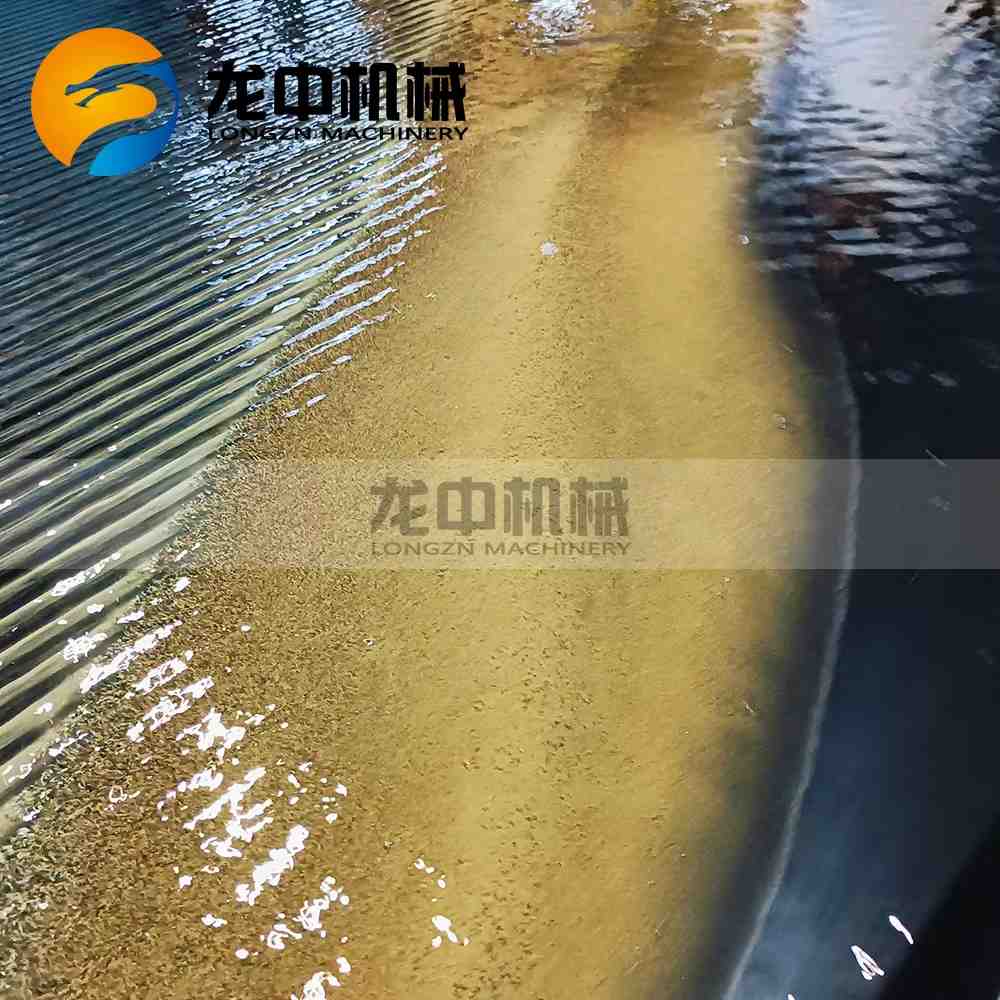

The working principle revolves around the combined action of asymmetric reciprocating motion of the deck and the transverse flow of water. Feed pulp is introduced at one corner. The shaking motion causes the particles to stratify by density on the inclined, riffled deck. Heavier, valuable minerals settle into the riffles and are carried longitudinally by the motion to the concentrate end. Lighter gangue particles are suspended and washed transversely across the deck by water flow to the tailings launder.

Its key advantages and characteristics include:

High-Precision Separation: Capable of producing high-grade concentrates and efficient separation of very close-density minerals.

Simplicity and Clarity of Operation: The separation zones (concentrate, middlings, tailings) are visually distinct and easily adjustable.

Low Operational Cost: Requires no reagents and has relatively low energy consumption compared to some other methods.

Environmentally Friendly: Purely physical gravity process, avoiding chemical pollution.、

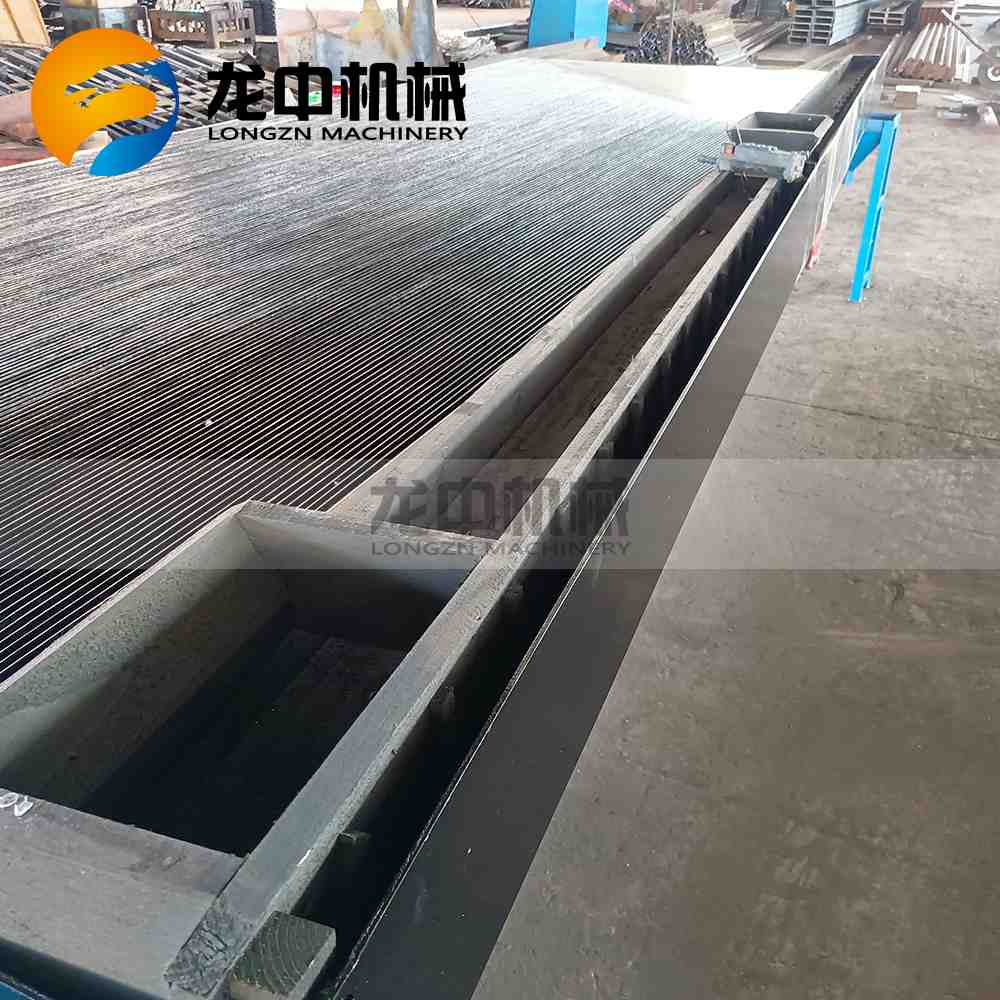

The main structural components of a standard shaking table are:

Deck (Table Surface): A flat, slightly inclined surface made of fiberglass or wood, covered with precisely designed riffles (lines).

Transmission (Head Motion) Mechanism: Provides the asymmetrical, slow-forward and fast-backward reciprocating motion. This is often a crank-rod or eccentric cam system.

Feed and Water Distribution Boxes: Ensure even distribution of feed pulp and wash water across the deck width.

Discharge Launders: Separate channels for collecting concentrates, middlings, and tailings.

Support Frame and Adjustable Base: Allows for precise adjustment of the deck's lateral slope and longitudinal tilt to optimize separation conditions.