Technical Transformation:

Upgrade and improve the ball mill equipment through technical transformation and optimization to enhance its output. This includes adjusting grinding process parameters such as the ball charge ratio, grinding media flow rate, and grinding time, as well as optimizing the mechanical structure of the grinding machinery to improve efficiency and processing capacity. Professional technical teams can be relied upon for process analysis and transformation design, formulating appropriate modification plans based on actual conditions.

Replacing with Larger Equipment:

If the existing ball mill cannot meet production requirements, consider replacing it with a larger model. Selecting a ball mill with higher processing capacity can increase the amount of material processed per grinding cycle, thereby boosting output. This requires comprehensive consideration of factors such as equipment spatial layout and power supply, along with thorough communication with suppliers to select a suitable larger model for replacement.

Optimizing Grinding Media Flow:

The flow state of grinding media significantly impacts grinding efficiency and output. By optimizing the flow pattern of grinding media, such as adjusting the feeding method, flow direction, and flow rate of the mill, the dispersion and grinding effect of materials during the process can be improved, leading to higher output.

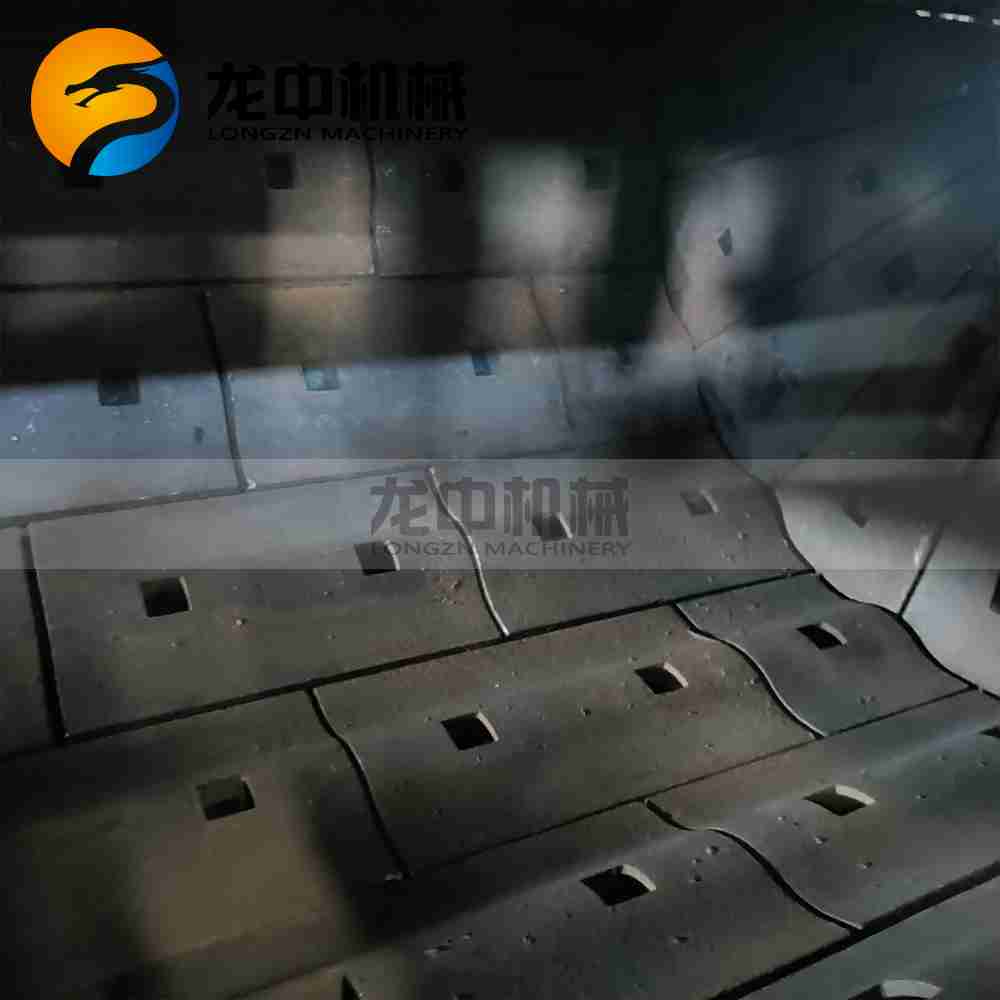

Detailed Optimization for Improved Grinding Efficiency:

Further enhance grinding efficiency and output through detailed optimization measures. For example, reasonably adjust the internal shape of the mill and the motion state of the grinding media to reduce energy loss and wear, thereby improving grinding efficiency. Increasing the grinding capacity of the mill can also enhance processing capability per unit time.

Regular Maintenance:

Regular maintenance of the ball mill is essential to ensure its normal operation and stable output. This includes periodic cleaning of the mill's interior, inspection and replacement of worn parts, and equipment lubrication to guarantee long-term stable performance and consistent production.

Strengthening Operation and Management:

Optimize operation and management to ensure the normal and efficient utilization of the ball mill equipment. Train operators to improve their skill levels, arrange production plan and technological process reasonably, and ensure the continuous and stable operation of the ball mill. Enhance equipment monitoring and data analysis to promptly identify issues and take corrective actions. Through refined management and optimized production processes, improve equipment utilization and production capacity.

Using High-Efficiency Grinding Media:

Select appropriate grinding media, such as high-efficiency grinding balls or high-pressure roller grinding medium, to improve grinding efficiency and output. These grinding media offer better grinding effects and wear resistance, reducing energy loss and wear while increasing production.

Optimizing the Feeding System:

Improve the design and operation of the feeding system to ensure uniform material feeding and proper flow control. By reasonably adjusting the feed particle size and distribution, avoid the negative impact of overly coarse or fine particles on grinding efficiency, thereby enhancing output.

Applying Advanced Automated Control Systems:

Introduce advanced automated control systems to achieve intelligent management and control of the ball mill equipment. Through precise data monitoring and analysis, promptly adjust operational parameters, optimize equipment performance, and increase output. Automated control systems also enable remote monitoring and fault diagnosis, improving equipment stability and reliability.

Considering Peripheral and Auxiliary Equipment Optimization:

The output of the ball mill is influenced by peripheral and auxiliary equipment. Ensure the proper integration of peripheral equipment, such as feeders and conveyors, and the normal operation of auxiliary equipment, such as dust removal systems and cooling systems. Optimizing the performance and operation of these supporting devices can help improve the overall output of the ball mill.

In summary, when the output of a ball mill is low, measures such as technical transformation, replacing with larger equipment, optimizing grinding media flow, detailed optimization, regular maintenance, strengthening operation and management, using high-efficiency grinding media, optimizing the feeding system, applying automated control systems, and considering peripheral and auxiliary equipment optimization can be taken to enhance production. Based on actual conditions, comprehensively evaluate and implement appropriate measures to ensure the ball mill equipment meets the expected output requirements.