The mined lateritic chromite ore is first fed into a rotary scrubber. During rotation, water flushing and mutual friction remove the clay impurities adhering to the ore surface.

The washed raw ore is further processed by a vibrating screen to separate particles smaller than 1.5 mm (which have the highest chromium content).

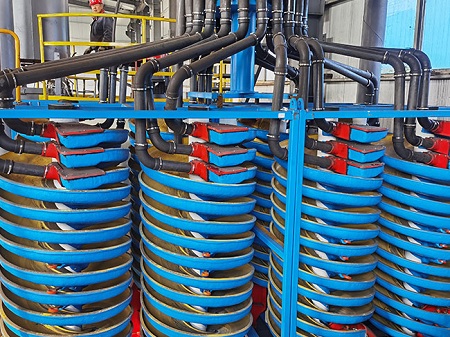

The core equipment for lateritic chromite ore beneficiation is the spiral chute. The ore slurry flows downward along the spiral chute, utilizing the density difference between chromite minerals and gangue to achieve separation. The first chute separation produces rough concentrate, the second re-separates the rough concentrate, and the third refining step yields the final concentrate.

The chromite concentrate often contains a small amount of magnetic iron mineral impurities. A wet permanent magnetic separator is used for iron removal to obtain high-quality chromite concentrate.